Excel Quality Tools

Design and Process FMEA

FMEA is a quality method to both identify and evaluate possible errors. The acronym comes from the FMEA Failure Mode and Effect Analysis. As the interest has increased for various quality management methodologies, also the use of FMEA has spread. Large manufacturing companies often requires of their suppliers to use FMEA in the development of products and processes.

The main purpose of the FMEA is to identify possible errors or mistakes and causes and effects of these for a product or a process. FMEA is carried out in two different areas:

Design-FMEA performed during the development and construction work and aims to identifying faults and defects in a product or part.

Process-FMEA performed to examine a process and designed to identify problems in the process itself.

FMEA file helps you in a simple and structured way to implement the methodology of FMEA.

Files for the following tests are included:

- Design FMEA

- Process FMEA

Functional Scope

- clear and simple layout

- FMEA criteria always available

- automatic calculation of risk number (RPN)

- prepared for planned actions

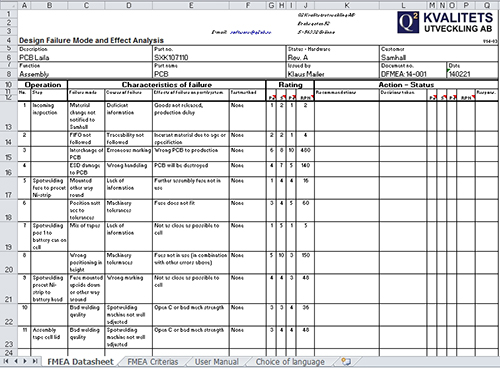

FMEA "Datasheet" - Sheet

Results of the analysis process and more information will be entered in this data sheet.

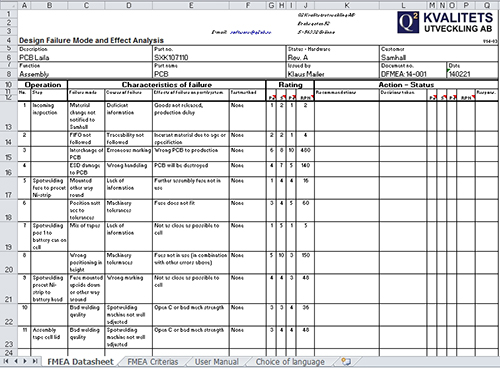

FMEA "Criterias" - Sheet

FMEA criteria for assessing risks are always available when processing.

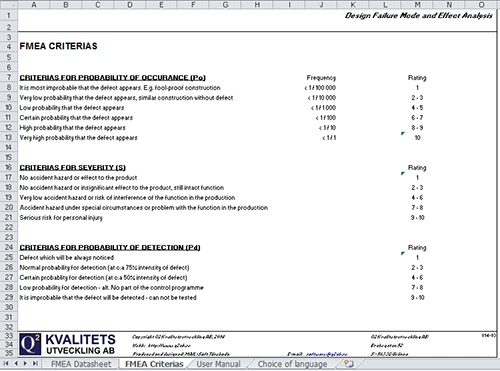

FMEA "User Manual" - Sheet

Here is a brief review of the theory behind FMEA and a description how to handle this tool.

Price

The price for the tool Design and Process FMEA is 1.750 SEK excl. VAT.

Ordering

To order Excel Quality Tools please use the

electronic order form.

The copyright of the Excel files is owned by Q2 Management Development AB. It is impermissible

to copy, modify, distribute, promote or sell multiple or single files, unless written

permission has been given from Q2 Management Development AB.

The Excel files are designed and developed by Q2 Management Development AB.